Case study

PVC Industrial Doors

THE PROJECT

Rooted in the rich tradition of Italian manufacturing, CV Teloni is looking ahead — choosing advanced automation by Cutting Edge Automation Machines to modernize a critical stage of its production: cutting PVC tarpaulins to produce high speed doors, tunnels and industrial covers.

Driven by a strong culture of innovation and continuous improvement, the company set three strategic goals:

- Increase operational efficiency

- Further enhance the quality of the finished product

- Reduce the burden of the most labor-intensive manual tasks

Automating PVC cutting process — a key phase where speed, precision, and repeatability directly impact the end product — has proven to be a decisive step in raising production standards and strengthening CV Teloni’s long-term competitiveness

THE PROCESS

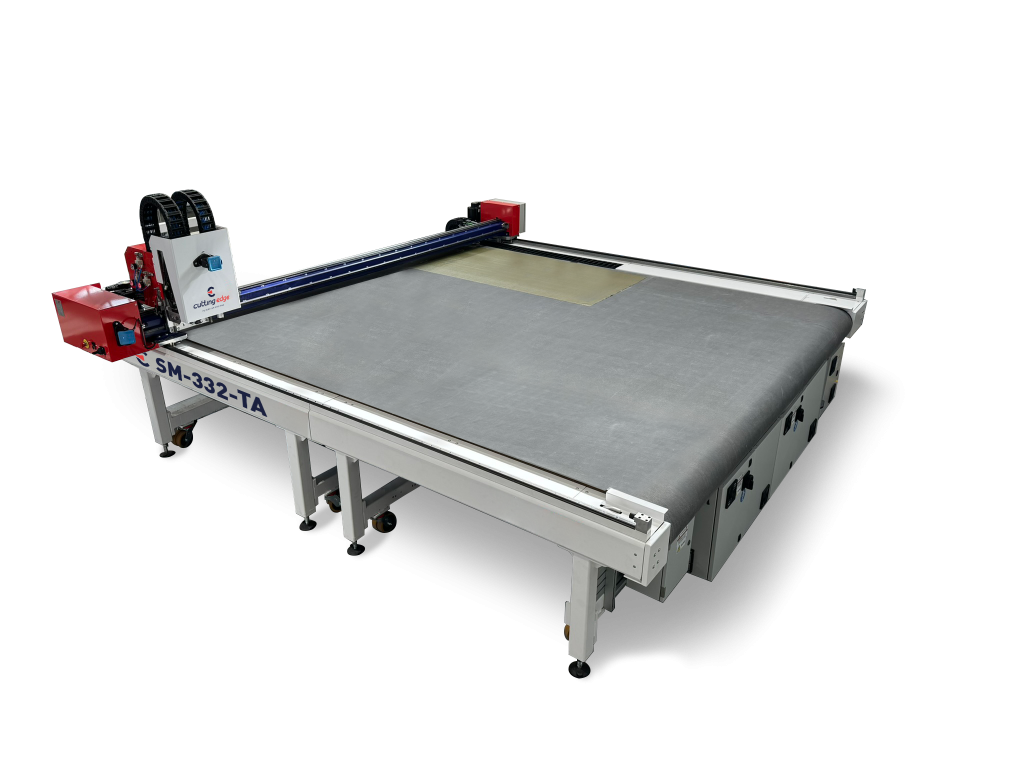

After a thorough analysis of CV Teloni’s production needs and workflow, we recommended the implementation of our SM-332-TA — a cutting machine equipped with a rotary conveyor belt, a cutting head capable of housing multiple interchangeable tools depending on cutting requirements, integrated safety systems, and PVC roll unwinder

This configuration enabled the company to:

- Perform continuous, high-precision cuts on PVC materials

- Increase productivity through process automation

- Enhance cutting quality by reducing waste and inaccuracies

- Streamline operator tasks by minimizing manual intervention

The machine’s robust structure is perfectly suited to sustain high workloads, even with very heavy PVC rolls.”

– G. Comero, CV Teloni

The collaboration with CV Teloni showcases how technology and craftsmanship can not only coexist but enhance one another within a single production environment. It’s a perfect synergy between automation and artisanal care — one that elevates the quality of the final product, maximizes operational efficiency, and highlights the unique strengths that define CV Teloni.

See photos and videos

SM-332-TA

Digital Cutting Plotter with Conveyor Belt

Discover the machine