Case study

Night and day roller blinds

THE PROJECT

One of the leading Spanish manufacturers of roller blinds was looking for a solution to produce square and rectangular panels from hard-to-handle materials like night and day and Screen fabrics. The process required extreme precision: roller blind panels must be perfectly squared to ensure perfectly straight roll up and down. Since the edges of the blinds remain visible, the cuts needed to be exceptionally clean and seared to prevent fraying.

THE PROCESS

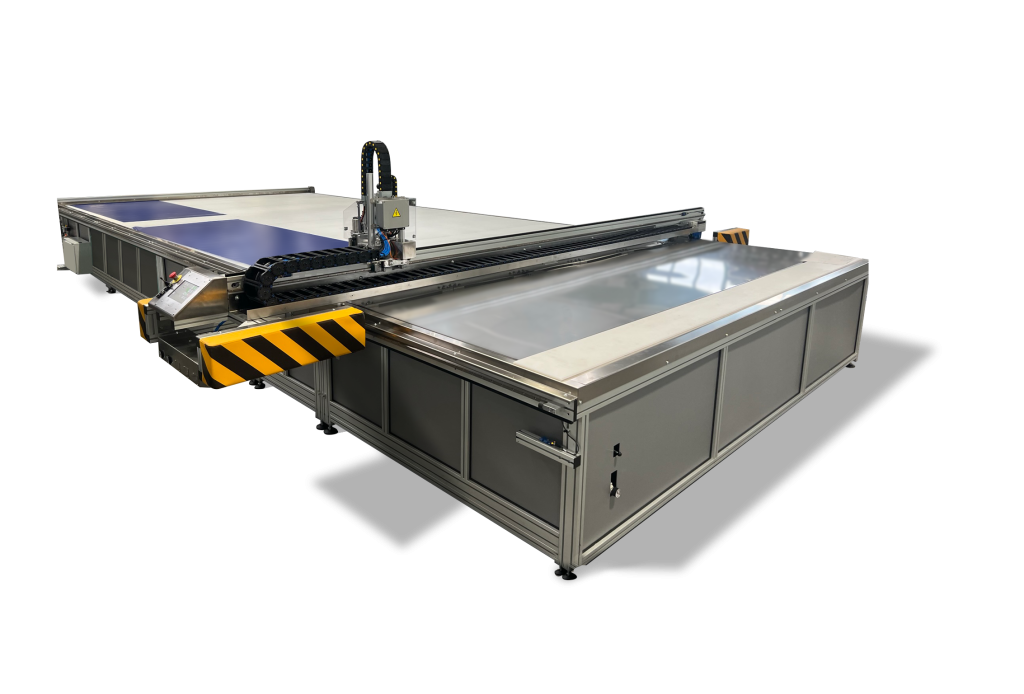

We provided a CAD/CAM cutting plotter equipped with a specially designed ultrasonic cutting head to ensure clean and sealed cuts. To secure the fabric on the work surface, we modified the grip and feed system so it can hold the zebra fabric firmly during cutting along the X-axis.

We also installed a linear laser pointer on the machine bridge, allowing the operator to ensure the fabric is perfectly aligned with the cutting machine’s axes.

Since the customer uses not only zebra-fabrics but several other materials, such as Screen, blackout, Soltis and even acrylics, we installed an 80W laser cutting tool and a rotary blade next to the ultrasonic blade and made the Spanish SM-375-Ta a truly all-round cutting solution.

Discover the machine