Case study

Pergola production

THE PROJECT

One of the leading European manufacturers of large and extra-large high-end pergola systems was looking for a solution to automate its production and increase output volumes.

Poiché i sistemi di tende per pergole vengono costantemente aperti e chiusi, le saldature realizzate dalla macchina dovevano essere estremamente resistenti. Inoltre, trattandosi di pergole di fascia molto alta, era fondamentale che il risultato finale fosse anche esteticamente gradevole per valorizzare gli spazi esterni: piatto e senza pieghe.

THE PROCESS

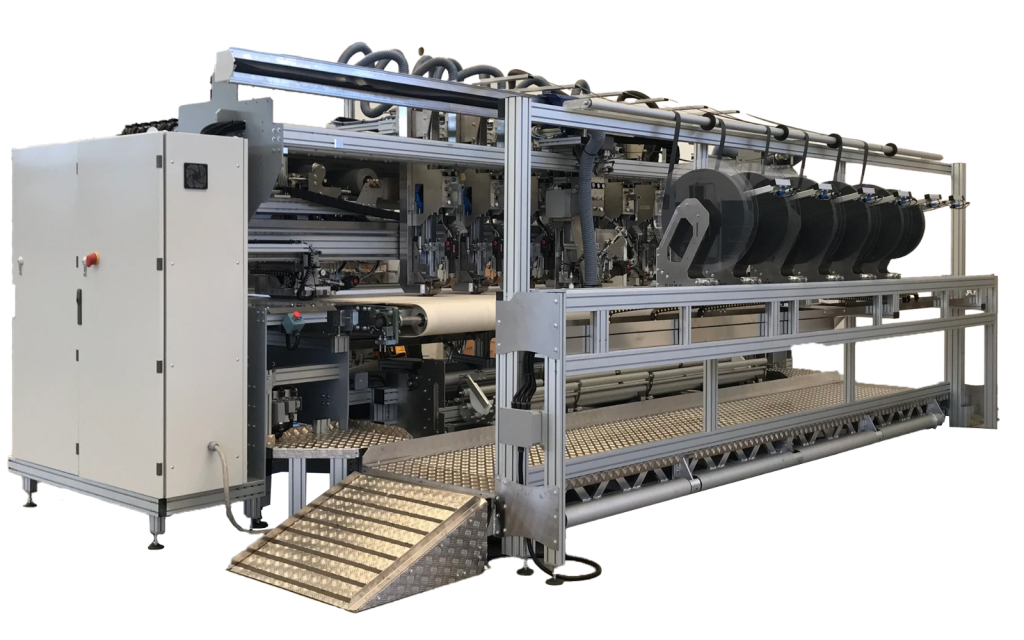

We adapted our SM-321-HA machine welding heads so that they could weld the omega profiles. Instead of welding 1 meter of omega profile at a time with the traditional HF technology, our machine applies up to 8 profiles simultaneously, at a speed of 6 meters per minute.

We increased our customer’s production output more than 20 times.

To facilitate the unloading of empty bobbins we installed a system that pneumatically lowers the bobbins so that the operator can easily reach them.

The motorized unwinder installed underneath the machine structure features digital control of the fabric edge and automatic correction of the position of the jumbo roll. A digitally controlled dancer continuously checks and corrects the tension of the fabric, to ensure welds of the highest quality and great precision even when making very large pergolas.

The machine is currently producing high-end pergolas in our custore’s manufacturing plant.

Discover the machine