Case study

Truck side curtains

THE PROJECT

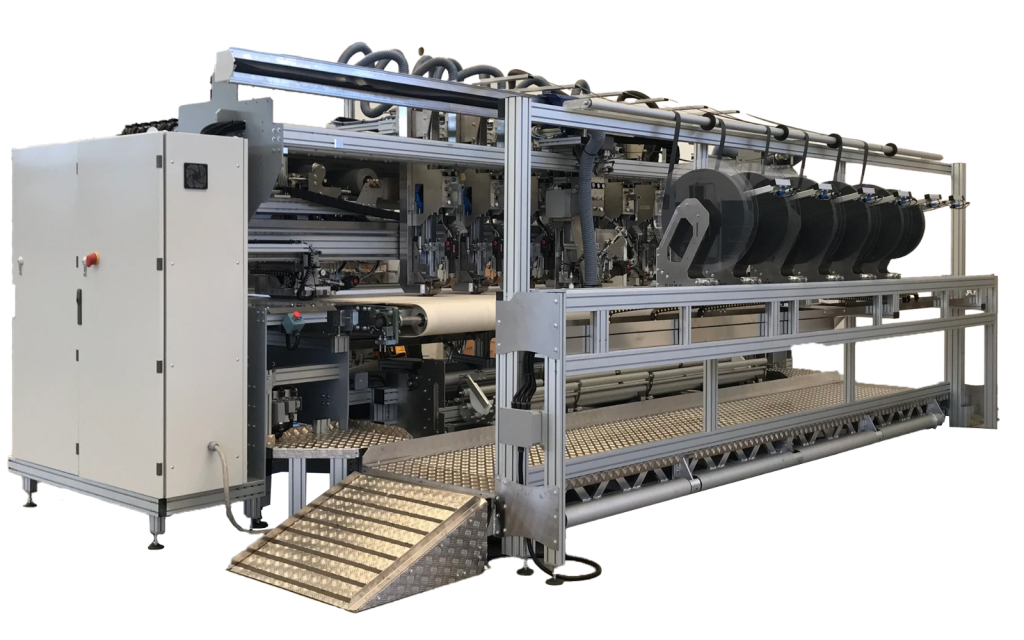

We built another unit of the SM-321-HA series, designed for the automatic production of side curtains for trailers.

This advanced machine makes a complete curtain including:

- 24 short vertical straps

- 15 vertical straps over the full curtain height

- 6 horizontal straps over the full curtain length (13,6 m)

- 5 vertical reinforcing belts (300 mm)

in just 20 minutes.

The improved vacuum surface sectioning on the conveyor belt, powerful welding heads, and a new smoke extraction system, make this machine an advanced and efficient side curtain welding station.

THE PROCESS

The machine can operate from a jumbo roll, or it can process individual pre-cut or pre-printed PVC panelswith speed and great precision. Curtains produced with this system have a length tolerance of only 2 mm over the full 13,6 m length.

A powerful vacuum turbine and sectioned conveyor belt hold the PVC panels perfectly flat during welding, minimizing wrinkles to an absolute minimum.

Webbing and vertical reinforcing belts are automatically cut.

Welding and cutting operations can be uploaded from a DXF drawing or set manually via the touch screen interface. The machine is operated by a single operator, with no special skills required.

See photos and videos

SM-321-HA

Multi-Tool Welding Machine with Conveyor Belt

Discover the machine