Case study

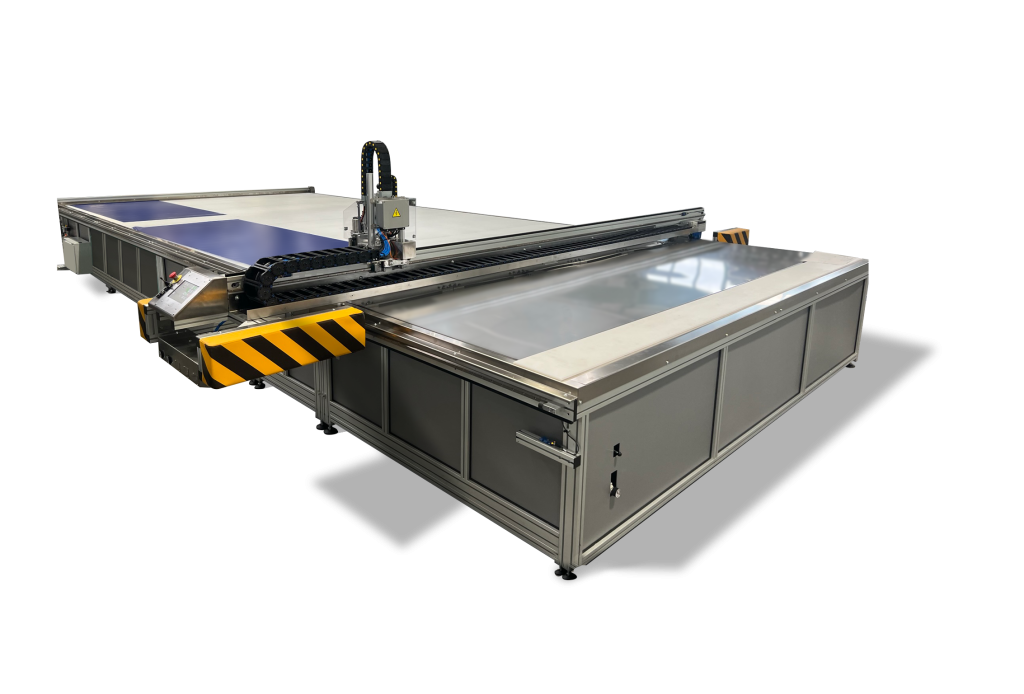

Multiple technologies fabric cutting

THE PROJECT

The largest roller blinds manufacturer in Brazil asked us to develop a custom cutting plotter capable of processing a wide variety of technical fabrics with a single machine. The company works with polyester, acrylic, PVC-coated fiberglass, blackout PVC, and crystal-clear PVC.

THE PROCESS

Based on the customer’s requirements, we decided for a cutting plotter from the SM-375-TA series. These machines can cut X-Y patterns, but also cut curves, circles, or even very complex shapes. SM-375-TA installs a wide range of cutting technologies. To make sure all fabrics our customer uses could be processed, we installed an ultrasonic blade, a rotary knife, a drag knife and a 30W laser cutting on the machine. The tool bridge also featureds a Teflon-coated pressing bar that slides over the fabric to hold it down during the length and cross cuts

A custom CAD software allows easy creation of squares, rectangles, and highly complex shapes, or the direct import of orders from the company’s database.

Discover the machine