Case study

Multi-roll welding machine for extra-large solar greenhouse panels

THE PROJECT

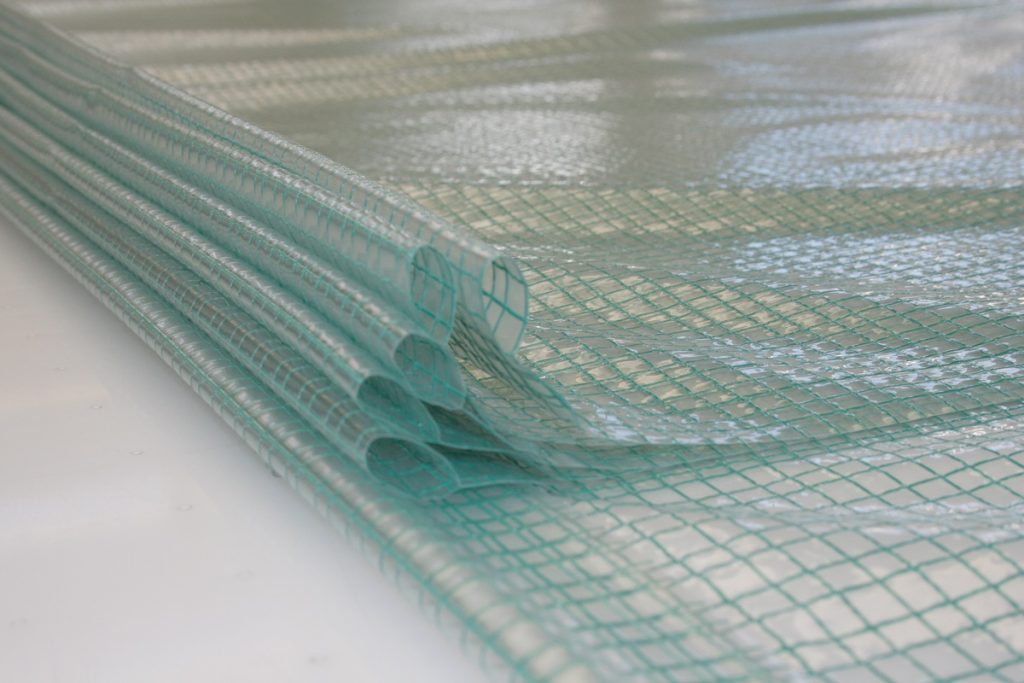

A manufacturer from Belgium needed to boost their production output of high quality greenhouses and agricultural covers in polyethylene (polythene) thermoplastic fabric. The sheets – widths up to 7 and lengths up to 11 m – and made of up to 4 individual panels welded together. The short sides of each panel needed a pocket with steel cable insert to mount the sheet over the aluminum greenhouse structure. The long sides had reinforcing hems. Once mounted on the structure, the sheets were subject to very high tension, so the seams needed to be extremely strong.

THE PROCESS

We developed a multiple-roll flatbed sealer that feeds the fabric from up to 4 motorized unwinding stations with automatic edge correction and digital fabric tension control. Three high-power hot air welding heads installed on the tool bridge join the panels together while 2 lateral heads create the left and right hems. The fabric is pulled off the rolls by an extra-large grip-and-pull system. Left and right hems and overlap seams are created simultaneously. A travelling rewinding station, placed behind the roll that is cut to size, collects the off-cut material, and rewinds it on a bobbin, ready for re-use.

After the creation of the sheet with left and right hem, the machine creates an air cushion allowing a single operator to transport the material to the back of the work surface. A connecting platform would allow the sheet to be placed on a second linear welding station that would create the pockets with steel cable.

In a few minutes, an extra-large greenhouse cover would be ready.

See photos and videos

SM-450-SA

Multiple roll digital welding machine

Discover the machine