Case study

Automatic welding process for pergolas

THE PROJECT

A leading manufacturer of high-quality pergola systems in Italy needed to significantly increase its production volumes. Until then, the production of pergola systems had been carried out manually. The company had decided to focus on large and extra-large pergola systems and was looking for a solution to speed up its traditional manufacturing processes.

The pergolas marketed by this Italian company were meant to be high-end and had to be aesthetically pleasing, with flat and wrinkle free seams.

THE PROCESS

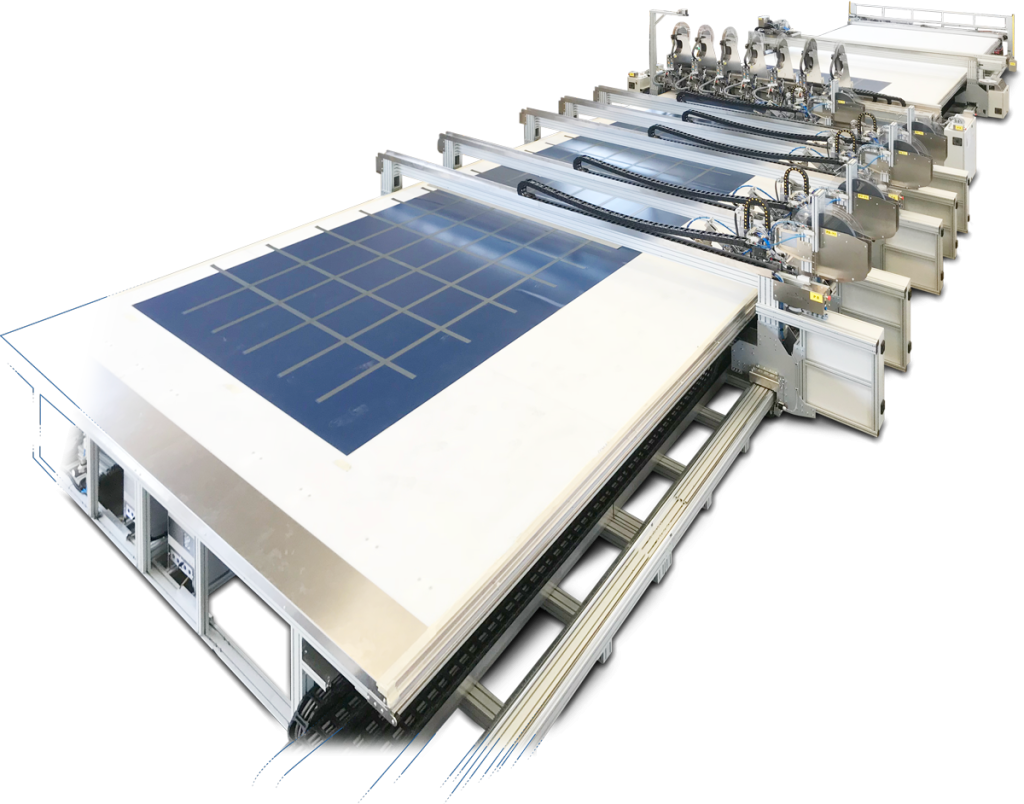

Based on our SM-370-HA flatbed welding plotter, we adapted the welding heads so that they could weld the omega profiles and anti-drip-profiles.

A single bridge, with 6 welding heads, moves over the PVC fabric, firmly kept in place on the massive 9 x 17 m work surface by 4 powerful vacuum turbines, and simultaneously applied up to 6 omega profiles or the anti-drip profiles on the left and right edges of the PVC. The machine installed a rotary cutting tool on the outer welding head to cut the PVC sheet to size during the welding cycle and save the time necessary for this otherwise consuming operation.

Since the machine was going to be used for high volume production and operated 6 days a week, we designed the structure to be extremely sturdy.

Our machine applies up to 6 profiles simultaneously, while cutting the fabric to size.

The machine can process either from the (jumbo) roll using the motorized unwinder in front of the machine or it can weld on precut sheets. The spreading of the PVC-coated panels is done automatically, by a heavy-duty grip-and-pull system.

See photos and videos

SM-370-HA

Flatbed welding machine for the production of Pergolas

Discover the machine