Case study

Truck Tarpaulins

THE PROJECT

One of the leading truck- tarpaulin and roof manufacturer in Europe requested a new machine with static bed to reduce cycle times and thus optimize production.

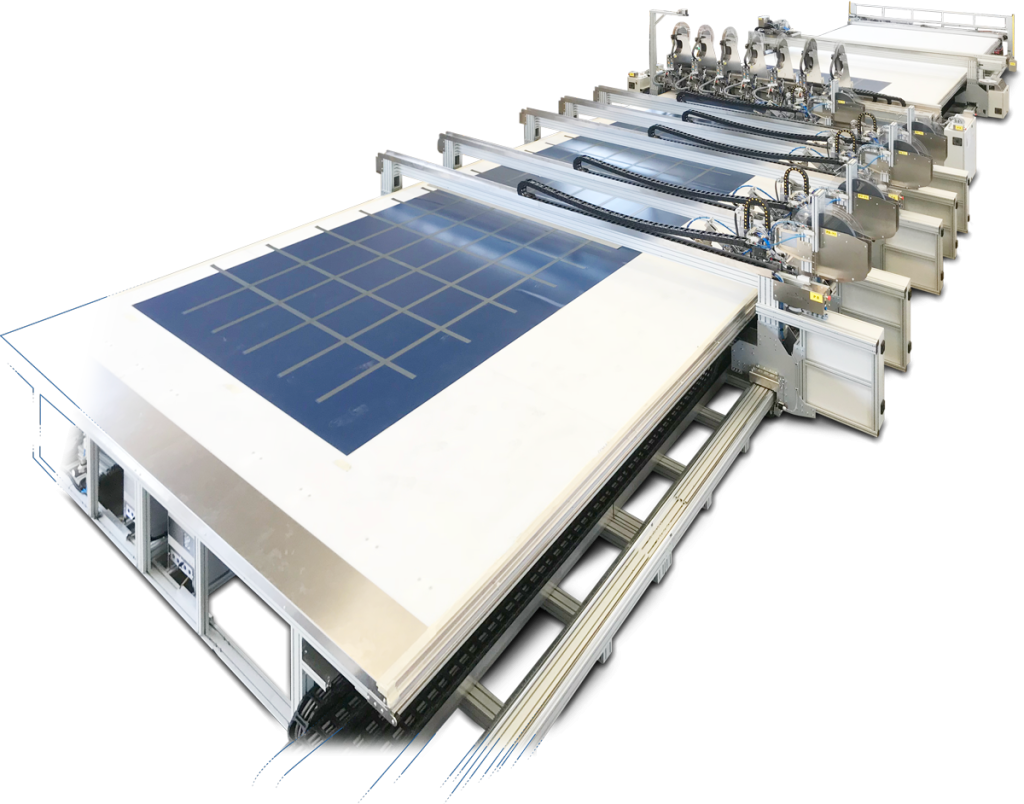

We developed the SM-370-HA.

This flatbed multiple tool, multiple bridge index welding machines is built for the fully automatic production of truck tarpaulin and roofs in record-breaking cycle times.

THE PROCESS

This machine features multiple travelling bridges, with each bridge installing multiple welding heads that apply

- the regular horizontal and vertical 50 mm straps

- the vertical reinforcing straps (up to 400 mm)

- the lower horizontal reinforcing strap

- even Velcro straps

The SM-370-HA can work from the jumbo roll, or it can process individual pre-printed or pre-cut panels. It can create a complete truck tarpaulin in approximately nine minutes.

A range of exclusively customized software programs makes this machine a complete manufacturing solution for your production requirements, to streamline your production processes with efficiency and quality required.

Increased production volumes. Top-quality products.

Since its inception, this machine has had several upgrades to make it even faster and more efficient.

The SM-370-HA can be customized to create standard trailer tarpaulins, roofs, or even anti-vandalism curtains with up to 13 horizontal and 12 vertical welding heads installed on multiple bridges, all working simultaneously and according to CAD drawings.

The SM-370-HA enables manufacturers of truck tarpaulins and roofs to deliver products of superior quality.

Fully automatic, highly efficient, and extremely precise.

See photos and videos

SM-370-HA

Flatbed Multi-Tool Welding Machine

Discover the machine