Case study

Extra large awnings

THE PROJECT

One of our key customers – a company from Belgium that already had two of our panel cutting machines, a cutting plotter and a welder with combined hot air and hot melt (liquid glue) technology to make pergolas, roller blinds and awnings – requested a custom sized plotter with rotary blades to square cut extra-large panels of welded or stitched-together screen materials used to make XXL roller blinds for public buildings.

THE PROCESS

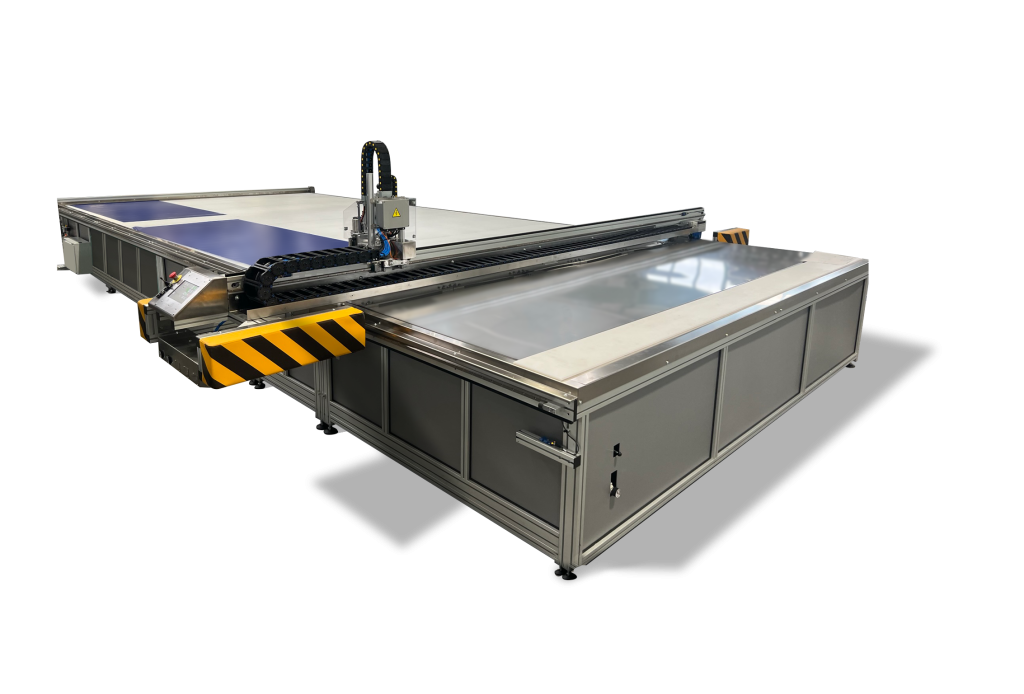

Based on the concept of one of our cutting plotters of the SM-375-TA series, we enlarged the machine structure and redesigned the bridge to make it strong enough to hold the multiple cutting tools on the cutting head without flexing a millimeter. The bridge also featured a Teflon-coated pressing bar that slides over the fabric to hold it down during the length and cross cuts to make sure the panels are perfectly square.

A custom CAD-software enables operators to easily create squares, rectangles and even highly complex patterns, or import orders from the company’s own order database.

Extra-large panels cut with great precision

The machine spreads the XXL panels automatically and with great efficiency. A powerful vacuum turbine secures the fabric to the cutting surface during the cut. The vacuum surface is sectioned so that, by concentrating the vacuumed power in a determined area, the machine can easily process smaller rolls or individual pieces of fabrics too.

See photos and videos

SM-375-TA

Digital cutting machine with static worktop

Discover the machine