Case study

Shade sails production

THE PROJECT

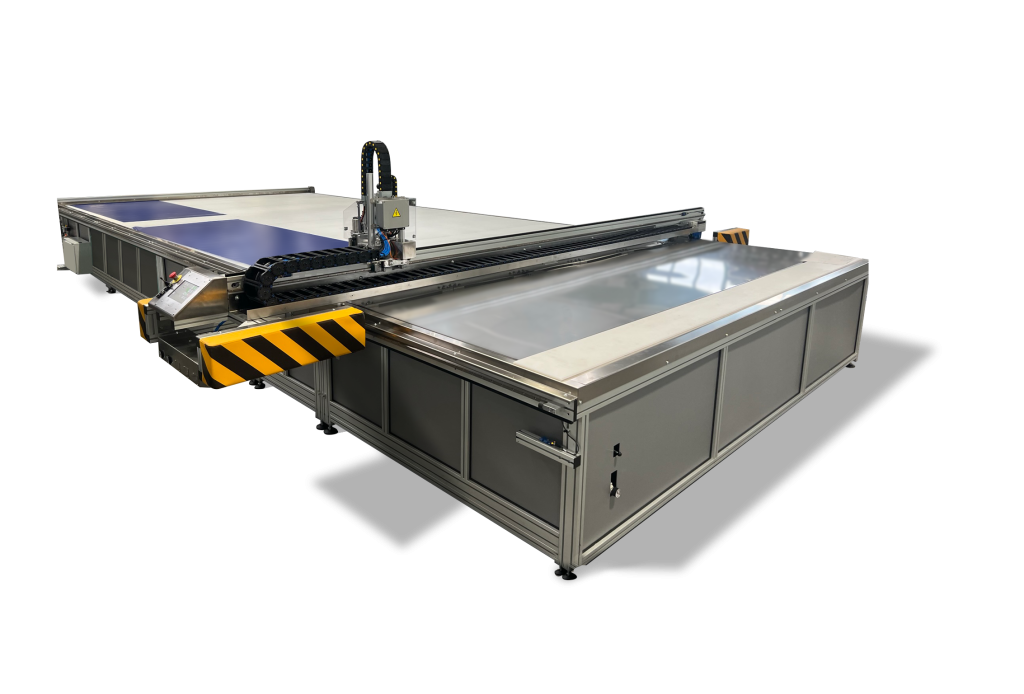

A company based in Istanbul turned to us for a cutting solution dedicated to the production of shade sails. These sails, made primarily from PVC-coated fabrics, can reach lengths of up to 21 meters. The customer was looking for a way to visually inspect the full pattern immediately after cutting. That’s why they chose our SM-375 series static-worktop cutting plotter — the ideal solution for precision, efficiency, and full-length fabric handling.

THE PROCESS

We built a large-format cutting plotter with a usable cutting length of 21 meters and a working width of up to 5 meters, equipped with all the essential tools for cutting heavy PVC-coated fabrics. These include 28 mm and 45 mm rotary blades for fast cutting of curves, straight lines, and simple shapes, a fixed blade for more complex patterns, and a marking pen to identify individual parts with a code or indicate reference points for subsequent welding or sewing operations.

With such a large cutting area, we installed two vacuum turbines and sectioned the work top into multiple areas, where vacuum power can be activated or deactivated depending on the size of the panels being cut. The turbines secure the fabric to the cutting surface during operation, but can also reverse the airflow to create a “flying carpet” effect on the worktop, making it easy to move large and heavy PVC sheets with minimal effort.

A custom CAD-macro makes the creation of very complex shape sails fast and easy, even for unskilled operators. Orders can also be imported from the company’s own order database.

Discover the machine