Case study

Roller Blinds Production

THE PROJECT

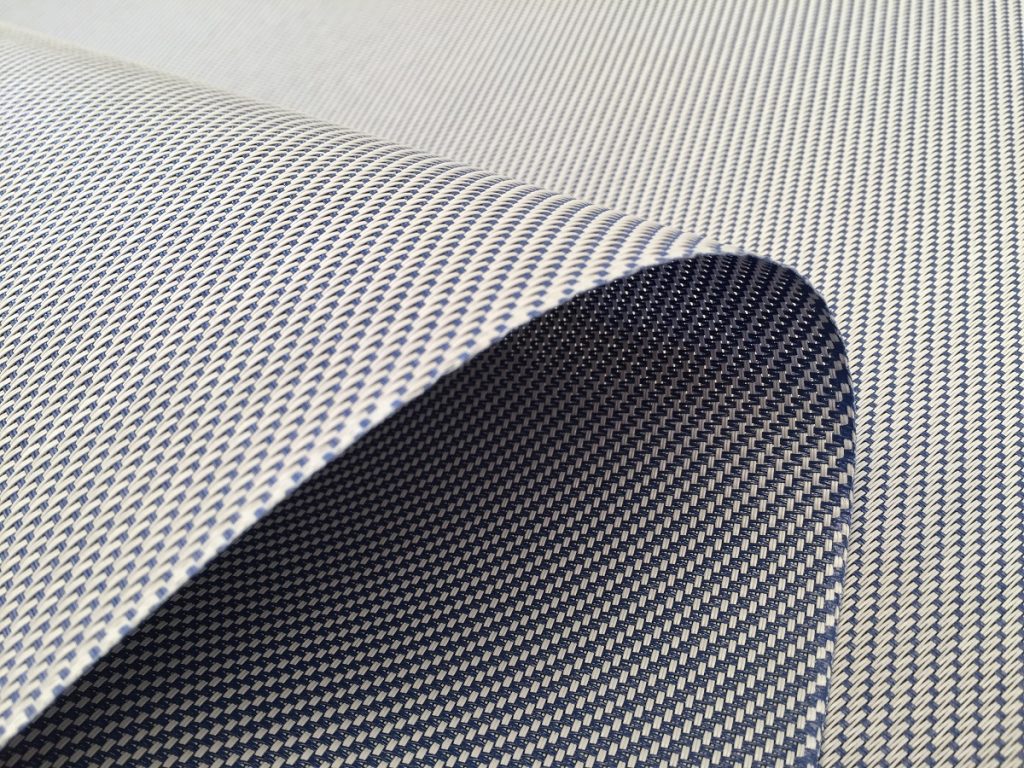

A leading US roller blind manufacturer asked us to develop a machine machine to create quality blinds in PVC-coated Screen fabrics. The panels had to be perfectly squared and, most importantly, the cuts needed a double seared edge: first by a hot wheel that rolls over the fabric during the pull, then by an ultrasonic knife. The customer also required the machine to be very compact and easy to use, with automatic fabric feeding and rewinding of the cut panel on the aluminum tube.

THE PROCESS

Our R&D team designed a machine able to process rolls up to 3,2 m wide. The rolls are placed on a roll holder and are fed into the machine by a set of motorized rollers that control the fabric during the full cutting cycle, creating just the right tension on the fabric during the cut. A clamping system on the rear of the machine rewinds the aluminum bar and the square cut Screen panel.

To ensure the double seared cut we developed a combined hot air/ultrasonic tool. A hot air blower heats a wheel that rolls over the fabrics prior to the cut and creates a pre-welded track (3 mm wide) on the Screen material. A powerful ultrasonic cutter then slices the fabric perfectly straight and in the middle of the hot wheel track, searing the cut again.

Perfectly seared edges, great precision.